The Oast

The oast house at Great Dixter is a reminder of the time when growing hops was very important to farming in the Weald of East Sussex and Kent.

The dried flower of the hop plant is used in brewing to give beer its distinctive flavour. It is a climbing plant that was trained to grow up strings supported by a network of long poles arranged across the fields. The woodlands of the area supplied the chestnut poles and also produced the charcoal once used in the furnaces of the oast houses where the hops were dried after picking.

The dried flower of the hop plant is used in brewing to give beer its distinctive flavour. It is a climbing plant that was trained to grow up strings supported by a network of long poles arranged across the fields. The woodlands of the area supplied the chestnut poles and also produced the charcoal once used in the furnaces of the oast houses where the hops were dried after picking.

The oast house at Great Dixter is a reminder of the time when growing hops was very important to farming in the Weald of East Sussex and Kent. The dried flower of the hop plant is used in brewing to give beer its distinctive flavour. It is a climbing plant that was trained to grow up strings supported by a network of long poles arranged across the fields. The woodlands of the area supplied the chestnut poles and also produced the charcoal once used in the furnaces of the oast houses where the hops were dried after picking.

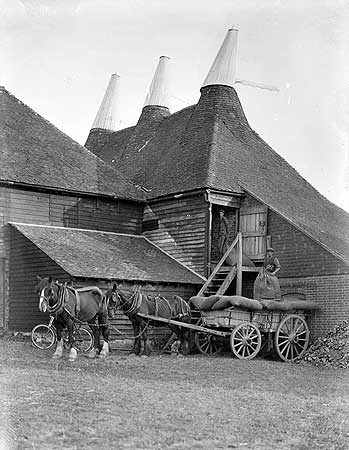

The existing Dixter oast house was constructed at the beginning of the 1890s to replace an earlier building close by of which nothing now remains. It has three square kilns side by side, each with a drying floor set over a furnace chamber below and with a cowl protruding above the roof at the top to create the draught for the fire. A passageway at ground level gives access to the three banks of furnaces.

Hops were normally harvested in early September. The long bines of the plant were cut down and the flowers picked off and collected. This was a long process when done by hand so it was common for extra workers to be hired, often families from London on a working holiday.

In the oast house, the picked hops were loaded onto the floor of each kiln, to a depth of about 60cm. The floors were slatted and covered in sections of cloth made from horse hair. These allowed the warm air to rise from the furnaces below without letting the hops drop through. When the hops had been dried enough, they were dragged through on the cloths to the upper floor of the barn attached to the kilns, tipped off and spread out to cool. Set into the barn floor is a hand-operated press into which the hops were carefully loaded using a special wood and hessian shovel called a scuppet. They were then compressed into a large sack, called a hop pocket, suspended below. The bulging pockets, weighing about 75kg each, were sewn up and stored ready for dispatch.

Dates recording the start of hop drying seasons can still be seen scrawled on the wooden joists supporting the barn floor. The series runs from September 7 1892, soon after the oast house was built, to September 5 1938, on the eve of the Second World War. Hop growing subsequently ceased at Dixter, as it eventually did on many other farms in the area for a variety of commercial reasons.